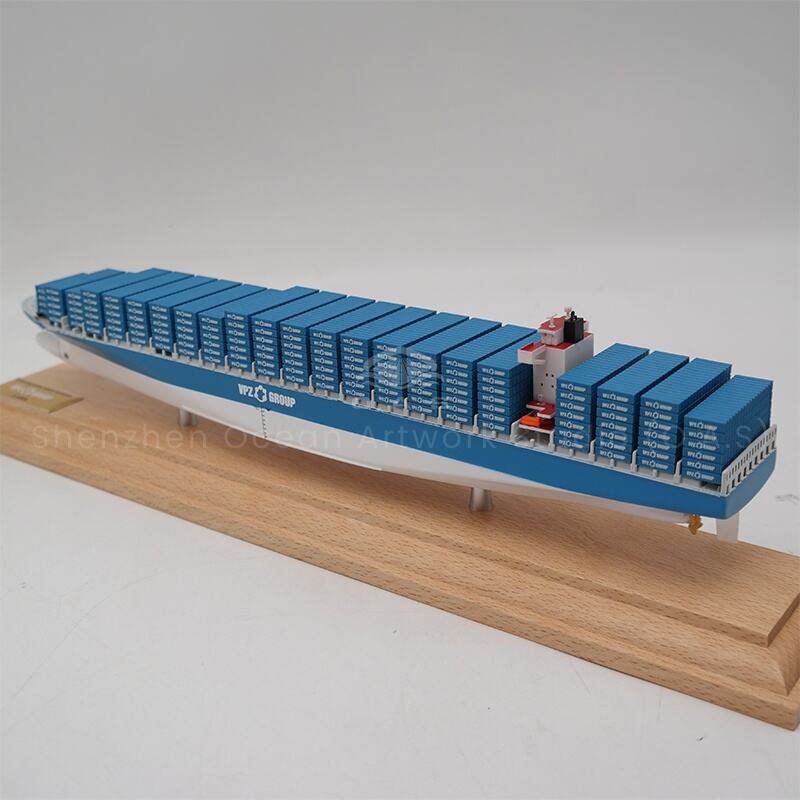

ship structure model

Ship structure model represents a comprehensive framework for analyzing, designing, and understanding vessel construction principles that form the backbone of modern maritime engineering. This sophisticated model encompasses the fundamental components that define how ships maintain structural integrity while operating in challenging marine environments. The ship structure model serves as a critical tool for naval architects, marine engineers, and shipbuilders who need to create vessels capable of withstanding enormous stresses from waves, cargo loads, and operational demands. At its core, the model addresses primary structural elements including the hull framework, deck systems, bulkheads, and reinforcement members that work together to create a seaworthy vessel. The technological features of this model incorporate advanced computational methods, finite element analysis, and stress distribution calculations that enable precise prediction of structural behavior under various loading conditions. Modern ship structure models utilize sophisticated software platforms that can simulate real-world scenarios, allowing designers to optimize material usage while maintaining safety standards. The model accounts for dynamic forces such as wave-induced bending moments, torsional stresses, and impact loads that vessels encounter during normal operations. Applications of the ship structure model span across multiple maritime sectors, including commercial shipping, naval defense, offshore platforms, and recreational boating industries. Ship designers rely on this model to determine optimal plate thickness, frame spacing, and material selection that balance structural strength with weight considerations. The model proves invaluable during the design phase, enabling engineers to identify potential weak points and implement reinforcement strategies before construction begins. Additionally, the ship structure model supports regulatory compliance by ensuring designs meet international standards for maritime safety and environmental protection. This comprehensive approach to vessel design significantly reduces the risk of structural failures, extends operational lifespans, and enhances overall maritime safety standards across the industry.