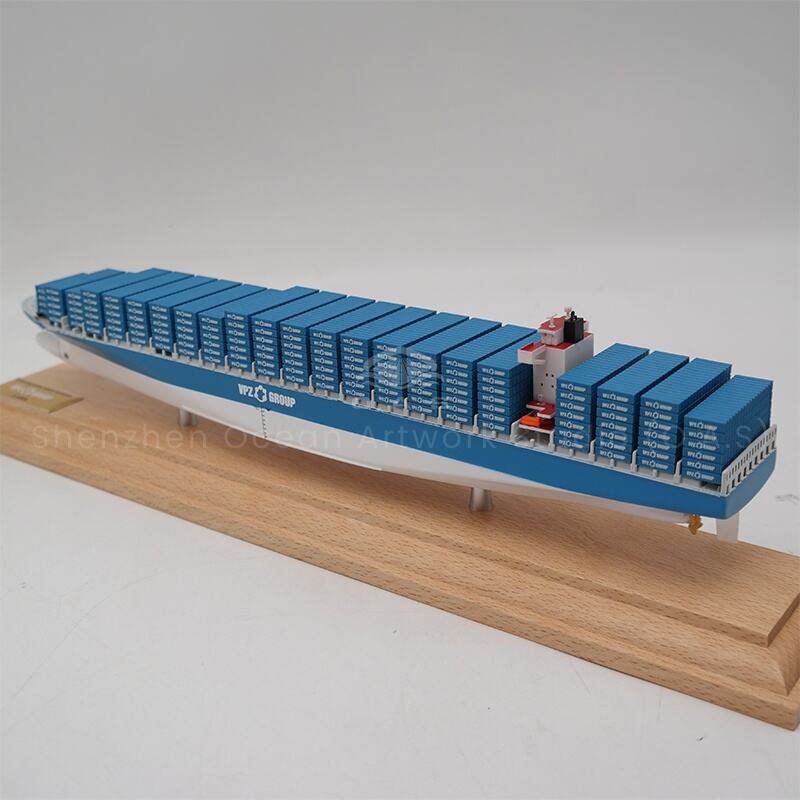

reinforced model container

The reinforced model container represents a revolutionary advancement in industrial storage and transportation solutions, designed to meet the demanding requirements of modern logistics and manufacturing operations. This specialized container system incorporates enhanced structural engineering principles that significantly exceed traditional container capabilities. The reinforced model container features advanced materials integration, including high-tensile steel frameworks, composite reinforcement panels, and specialized coating systems that provide superior protection against environmental factors and mechanical stress. The primary functions of the reinforced model container encompass secure storage, reliable transportation, and versatile deployment across multiple industrial sectors. These containers utilize innovative design methodologies that optimize load distribution while maintaining structural integrity under extreme conditions. The technological features include precision-engineered corner castings, reinforced sidewall construction, and advanced locking mechanisms that ensure cargo security throughout transit and storage phases. The reinforced model container incorporates modular design principles that allow for customizable configurations based on specific operational requirements. Applications span across maritime shipping, rail transportation, construction sites, military operations, and temporary facility deployment. The container's enhanced durability characteristics make it particularly suitable for harsh environmental conditions, including extreme temperatures, corrosive atmospheres, and high-impact scenarios. Manufacturing processes for the reinforced model container involve sophisticated welding techniques, quality control protocols, and rigorous testing procedures that guarantee performance standards. The container's versatility extends to specialized applications such as equipment housing, mobile workshops, emergency response units, and secure storage facilities. Integration capabilities allow the reinforced model container to interface seamlessly with existing logistics infrastructure while providing enhanced operational efficiency and reduced maintenance requirements compared to conventional container solutions.