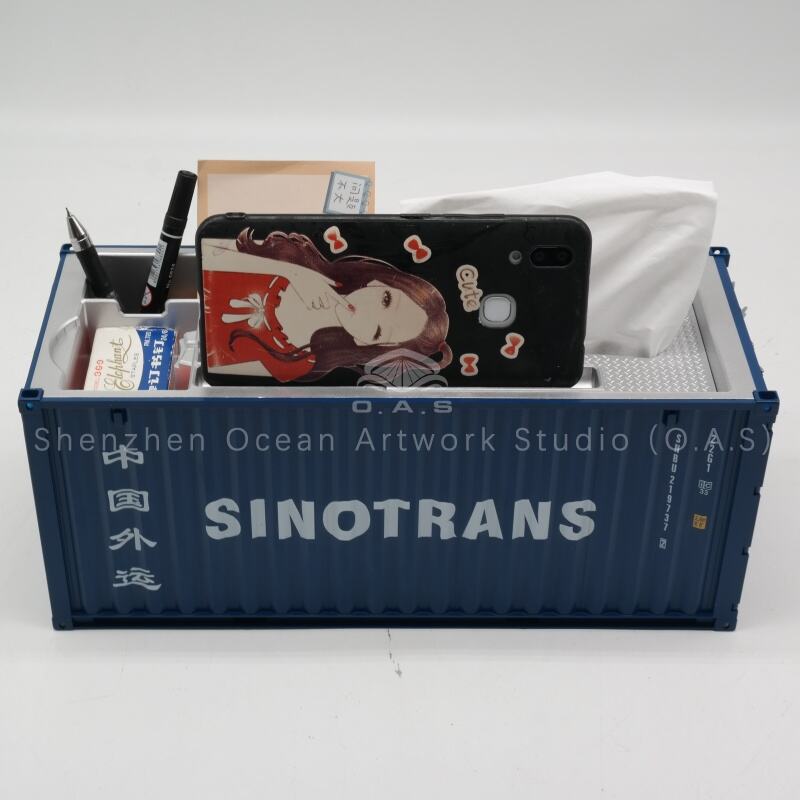

container model craftsmanship

Container model craftsmanship represents a revolutionary approach to modern manufacturing and prototyping that combines precision engineering with innovative design methodologies. This sophisticated technique involves creating detailed scale models and functional prototypes using containerized production systems that enhance accuracy, efficiency, and scalability. The container model craftsmanship process integrates advanced computer-aided design software with state-of-the-art manufacturing equipment housed within modular container units. These self-contained production facilities enable manufacturers to create highly detailed models with exceptional precision and consistency. The main functions of container model craftsmanship include rapid prototyping for product development, architectural visualization through detailed scale models, and educational demonstrations for training purposes. The technology features cutting-edge 3D printing capabilities, precision CNC machining, laser cutting systems, and automated quality control mechanisms. These technological components work together seamlessly to produce models that meet exact specifications while maintaining cost-effectiveness. Applications span across multiple industries including automotive design, aerospace engineering, architectural planning, medical device development, and consumer product manufacturing. The containerized nature of this craftsmanship allows for mobile production capabilities, enabling on-site model creation and immediate client collaboration. Environmental sustainability remains a core focus, with energy-efficient systems and recyclable materials integrated throughout the production process. Quality assurance protocols ensure that every model meets stringent accuracy standards, with digital verification systems providing real-time monitoring of production parameters. The container model craftsmanship methodology transforms traditional modeling approaches by offering faster turnaround times, reduced material waste, and enhanced collaborative opportunities between designers, engineers, and clients.