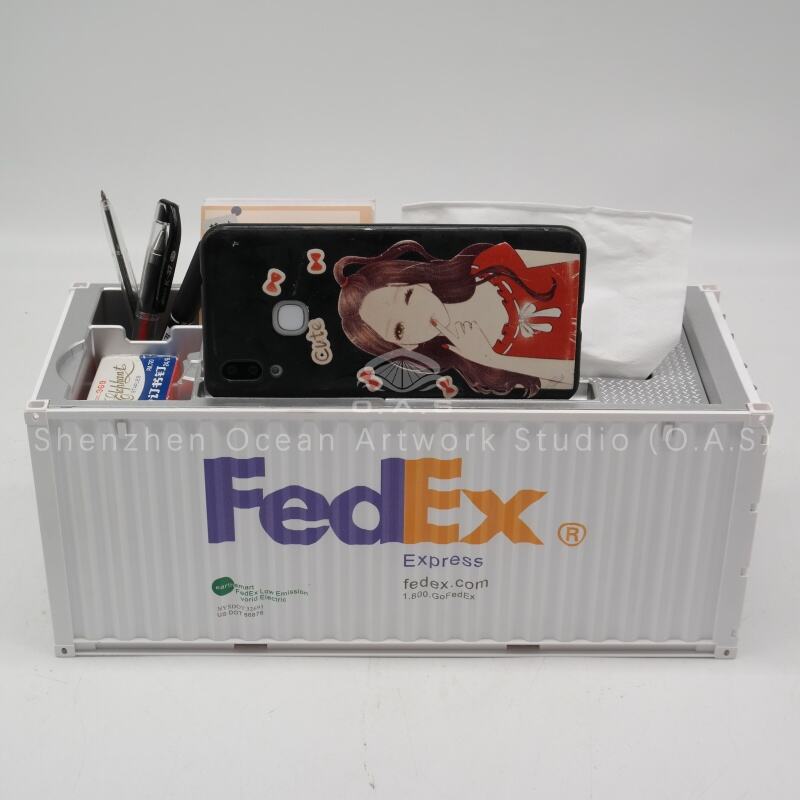

container model scale

The container model scale represents a revolutionary advancement in portable weighing technology, designed specifically for logistics, shipping, and industrial applications where precision and mobility are paramount. This innovative weighing solution integrates sophisticated load cell technology within a compact, containerized framework that can be easily transported and deployed across multiple operational sites. The container model scale operates through advanced digital sensors that capture weight measurements with exceptional accuracy, typically achieving precision levels within 0.1% of full scale capacity. Its robust construction features weatherproof housing that withstands harsh environmental conditions, making it suitable for outdoor installations and marine environments. The system incorporates state-of-the-art microprocessor technology that processes weight data in real-time, providing instant digital readouts through multiple display options including LCD screens, wireless connectivity, and mobile device integration. One of the most significant technological features of the container model scale is its modular design architecture, which allows for customizable configurations based on specific operational requirements. The scale platform can accommodate various container sizes and weight capacities, ranging from small shipping containers to large industrial vessels. Advanced calibration systems ensure consistent accuracy across different temperature ranges and environmental conditions, while built-in diagnostic features provide continuous monitoring of system performance. The container model scale finds extensive applications across diverse industries including maritime shipping, freight transportation, warehouse management, and manufacturing operations. Port facilities utilize these scales for efficient cargo processing, enabling rapid weight verification of shipping containers during loading and unloading procedures. Manufacturing plants deploy container model scales for inventory management, production monitoring, and quality control processes. The transportation sector benefits from their portability, allowing weight verification at multiple checkpoints along supply chain routes. Additionally, the container model scale serves recycling centers, mining operations, and agricultural facilities where bulk material measurement is essential for operational efficiency and regulatory compliance.