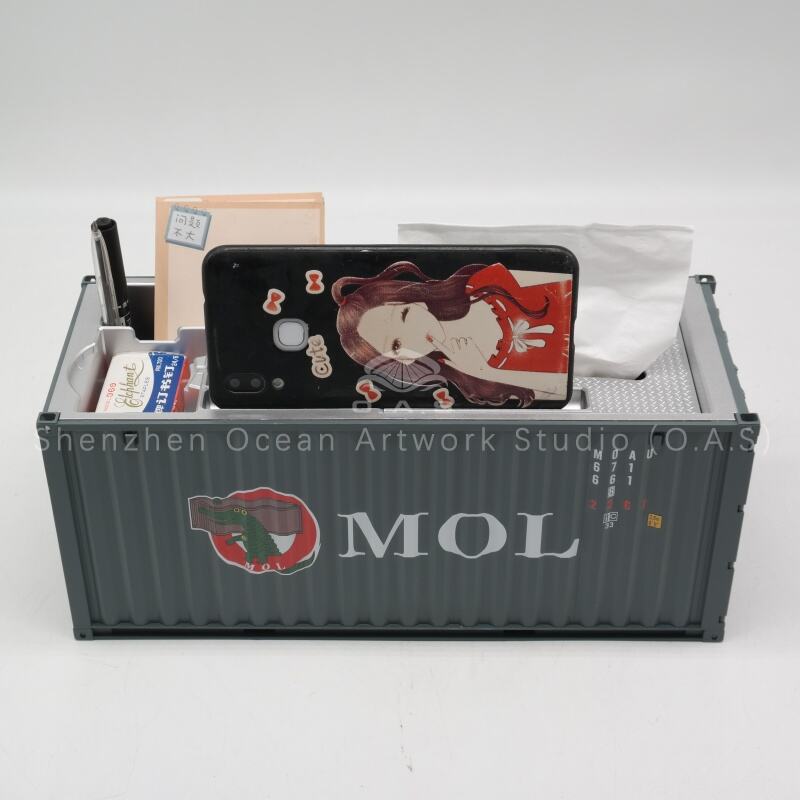

container model craftsmen

Container model craftsmen represent a revolutionary approach to modern manufacturing and design, combining traditional craftsmanship with cutting-edge containerized technology solutions. These specialized professionals excel in creating precise, scalable models within standardized container frameworks, delivering exceptional quality and efficiency across various industries. The container model craftsmen utilize advanced digital fabrication techniques, including 3D printing, CNC machining, and automated assembly processes, all housed within portable container units that can be deployed anywhere manufacturing needs arise. Their primary functions encompass rapid prototyping, small-batch production, custom manufacturing solutions, and on-site fabrication services. The technological features of container model craftsmen include state-of-the-art equipment integration, real-time quality control systems, environmental monitoring capabilities, and seamless connectivity with cloud-based design platforms. These mobile manufacturing units incorporate sophisticated ventilation systems, precision temperature control, and advanced safety protocols to ensure optimal working conditions. Container model craftsmen applications span across aerospace, automotive, medical device manufacturing, architectural modeling, consumer electronics, and educational institutions. The versatility of these containerized workshops allows for rapid deployment to remote locations, disaster relief areas, or temporary project sites where traditional manufacturing facilities are unavailable. Each container model craftsmen unit features modular design elements that enable quick reconfiguration based on specific project requirements. The integration of IoT sensors and smart monitoring systems provides real-time data analytics, predictive maintenance alerts, and performance optimization insights. These professionals leverage collaborative robotics, artificial intelligence-assisted design tools, and sustainable manufacturing practices to minimize waste and maximize resource efficiency. The container model craftsmen approach transforms traditional manufacturing paradigms by offering unprecedented flexibility, mobility, and customization capabilities while maintaining the highest standards of craftsmanship and precision engineering throughout every production cycle.