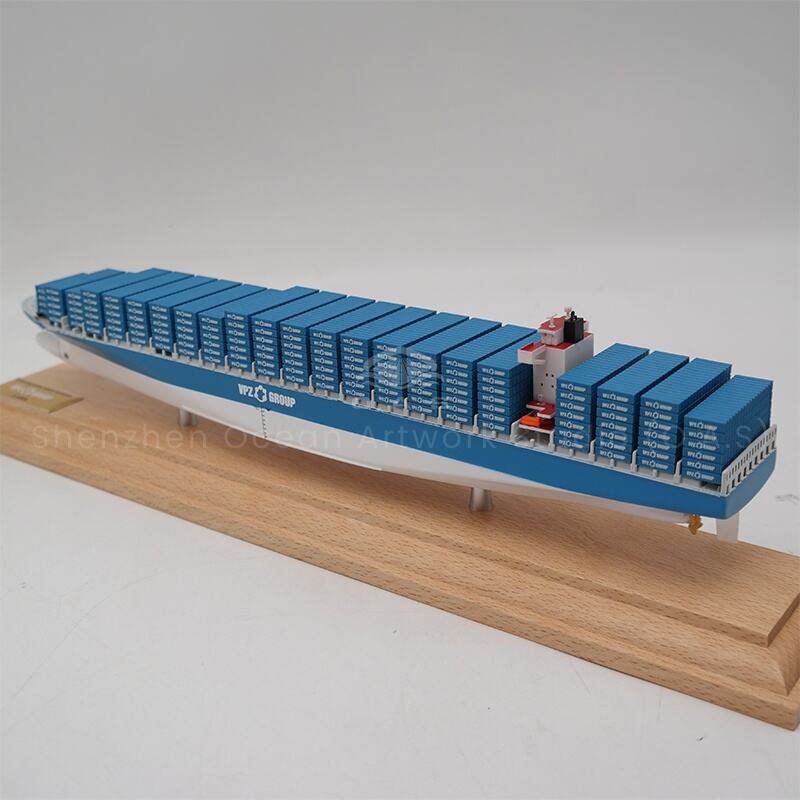

container model factory

A container model factory represents a revolutionary approach to manufacturing that transforms standard shipping containers into fully functional production facilities. This innovative concept combines mobility, efficiency, and scalability to create manufacturing solutions that adapt to diverse industrial needs. The container model factory integrates advanced manufacturing equipment, quality control systems, and automated processes within the standardized dimensions of shipping containers, typically measuring 20 or 40 feet in length. The main functions of a container model factory include complete product assembly, quality testing, packaging operations, and inventory management. These facilities can accommodate various manufacturing processes such as electronics assembly, textile production, food processing, pharmaceutical manufacturing, and automotive component production. The technological features of container model factory systems encompass modular design architecture, plug-and-play connectivity, climate control systems, advanced ventilation networks, and integrated power management solutions. Modern container model factory installations incorporate IoT sensors for real-time monitoring, automated material handling systems, robotic assembly lines, and sophisticated data analytics platforms. The applications span multiple industries including automotive manufacturing, consumer electronics production, medical device assembly, and specialty chemical processing. Container model factory solutions prove particularly valuable for companies requiring rapid deployment capabilities, seasonal production flexibility, or operations in remote locations. These facilities support just-in-time manufacturing strategies, enable distributed production networks, and facilitate market entry in new geographical regions. The container model factory concept addresses modern manufacturing challenges through standardized yet customizable solutions that maintain consistent quality standards while offering unprecedented operational flexibility and rapid scalability options for growing businesses.