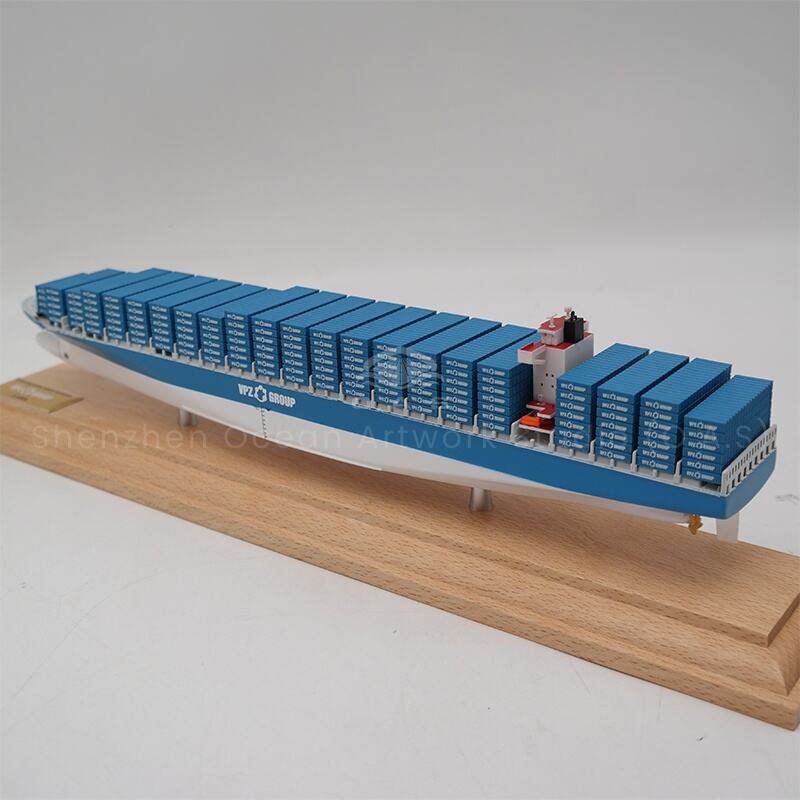

alloy container model

The alloy container model represents a revolutionary approach to industrial storage and transportation solutions, combining advanced metallurgical engineering with practical design principles. This innovative system utilizes specially formulated metal alloys to create containers that excel in durability, performance, and versatility across multiple industries. The alloy container model incorporates cutting-edge materials science, featuring corrosion-resistant properties that significantly extend service life compared to traditional storage options. At its core, the alloy container model delivers superior structural integrity through precision-engineered alloy compositions that withstand extreme environmental conditions, temperature fluctuations, and chemical exposure. The technological framework behind this container system includes advanced welding techniques, seamless construction methods, and rigorous quality control processes that ensure consistent performance standards. Key functions of the alloy container model encompass secure containment of various materials, protection against contamination, and reliable transportation capabilities for sensitive cargo. The model features modular design elements that allow for customization based on specific operational requirements, making it adaptable to diverse industrial applications. Manufacturing processes for the alloy container model involve sophisticated metallurgical techniques that optimize strength-to-weight ratios while maintaining cost-effectiveness. The containers incorporate smart design features such as reinforced stress points, ergonomic handling systems, and compatibility with standard transportation equipment. Primary applications span across chemical processing, pharmaceutical manufacturing, food and beverage industries, aerospace components, and hazardous material handling. The alloy container model demonstrates exceptional resistance to environmental factors including moisture, UV radiation, and chemical vapors that typically degrade conventional container materials. Advanced surface treatments and protective coatings further enhance the longevity and performance characteristics of these specialized containers, making them ideal for long-term storage and repeated use cycles.