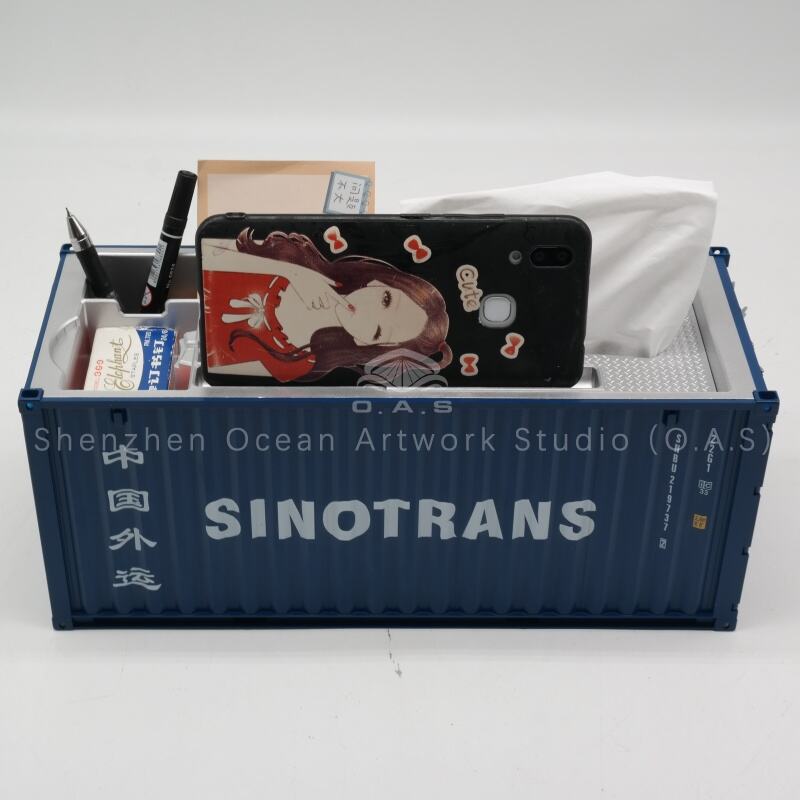

container model workmanship

Container model workmanship represents a revolutionary approach to manufacturing and construction that emphasizes modularity, precision, and efficiency. This innovative methodology transforms traditional production processes by creating standardized, interchangeable components that can be seamlessly integrated into various applications. The container model workmanship philosophy centers on developing self-contained units that maintain consistent quality standards while offering exceptional flexibility in deployment and configuration. The main functions of container model workmanship encompass design standardization, quality control optimization, and streamlined production workflows. This approach enables manufacturers to create products with predictable performance characteristics, reduced manufacturing variability, and enhanced scalability. The system facilitates rapid prototyping, accelerated time-to-market, and simplified maintenance procedures across diverse industry sectors. Technological features of container model workmanship include advanced modular design principles, precision engineering protocols, and integrated quality assurance systems. The methodology employs sophisticated computer-aided design tools, automated manufacturing processes, and rigorous testing procedures to ensure each container unit meets exacting specifications. These technological innovations enable consistent replication of successful designs while maintaining the flexibility to adapt to specific customer requirements. Applications of container model workmanship span numerous industries, including construction, manufacturing, logistics, and technology sectors. In construction, this approach enables rapid assembly of buildings using prefabricated modules. Manufacturing industries utilize container model workmanship to create standardized production lines and equipment configurations. Logistics companies benefit from standardized shipping containers and modular storage solutions. Technology sectors leverage this methodology for data center construction, telecommunications infrastructure, and portable equipment deployment. The versatility of container model workmanship makes it particularly valuable for projects requiring rapid deployment, cost efficiency, and scalable solutions across multiple locations and environments.