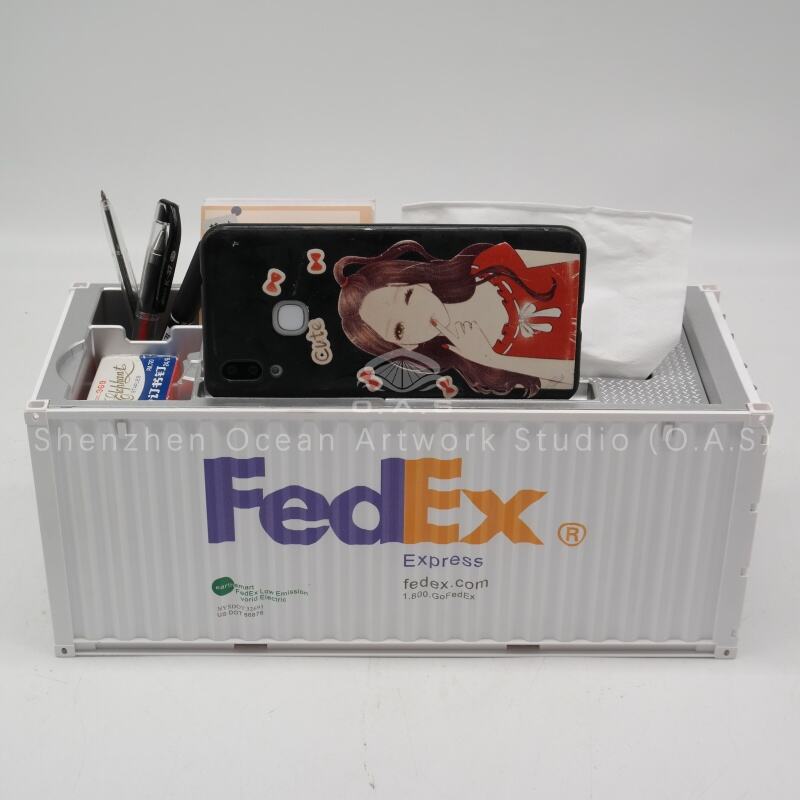

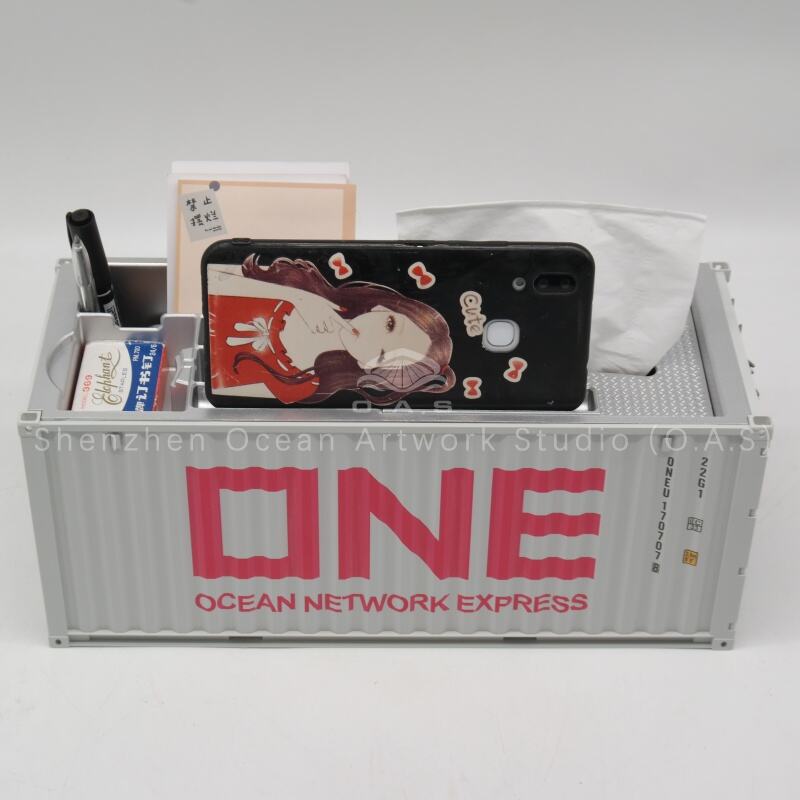

container modellus regulabilis

Contenitor modeli regolabilis solutionem revolutionariam in systematibus hodiernis servandi et transportandi repraesentat, quae ad postulata variantia variarum industrium accommodanda parata est. Hic systema continitoris innovativum facultates modificationis magnitudinis dynamicae habet, quae utentibus permittunt dimensiones secundum praescripta specialia adaptare. Contenitor modeli regolabilis principia ingenieriae provectae cum functione practica coniungit, eumque instrumentum necessarium reddens pro commerciis quae solutiones flexibiles servandi requirunt. Functio principalis continitoris circa servitium capacitis variabilis versatur, quod ad varias genera et volumina onerum accomodata est. Contra continitores tradicionales magnitudine fixa, contenitor modeli regolabilis per suam structuram expandibilem singularis varietas offert. Fundamentum technologicum in systematibus mechanicis precise factis innititur, quae integritatem structuralem servant, tamen simplicitatem operationalem retinent. Praecipuae notae technologicae sunt laminas parietum telescopicas, articulos angulares roboratos, et machinationes automatas adjustmentis, quae mutationes magnitudinis leves faciliant. Contenitor materiales altius firmitudinis ut tela ex aere galvanizato et laminas compositas resistentes meteoris utitur, quae durabilitatem per conditiones ambientales diversas garantunt. Machinae firmationis provectae continitorem in quovis situ configurato muniant, securitatem oneris durante periodos transportandi et servandi certantes. Applicationes in multis sectoribus patentes sunt, inter quos logistica, fabricatio, distributio mercatoria, et servi relationum emergentium. Contenitor modeli regolabilis praesertim utilis est in mercimoniis tempore annui variantibus, ubi necessitudines servandi per cyclorum operationum fere variant. Societates constructionum hos continitores ad servandum instrumenta utuntur, quae secundum phasibus profectionis et praescripta locorum variant. Operationes mercatoriae utilitatem continitoris capiunt, quae fluctuationibus inventarii durante temporibus summis et diebus promotionis satisfacit. Designatio modularis systematis usum efficientem spatii in horreis, portubus navium, et in locis servandi provisorius efficit, ubi optimizatio spatii directe in expensas operationales et gradus efficacitatis impingit.