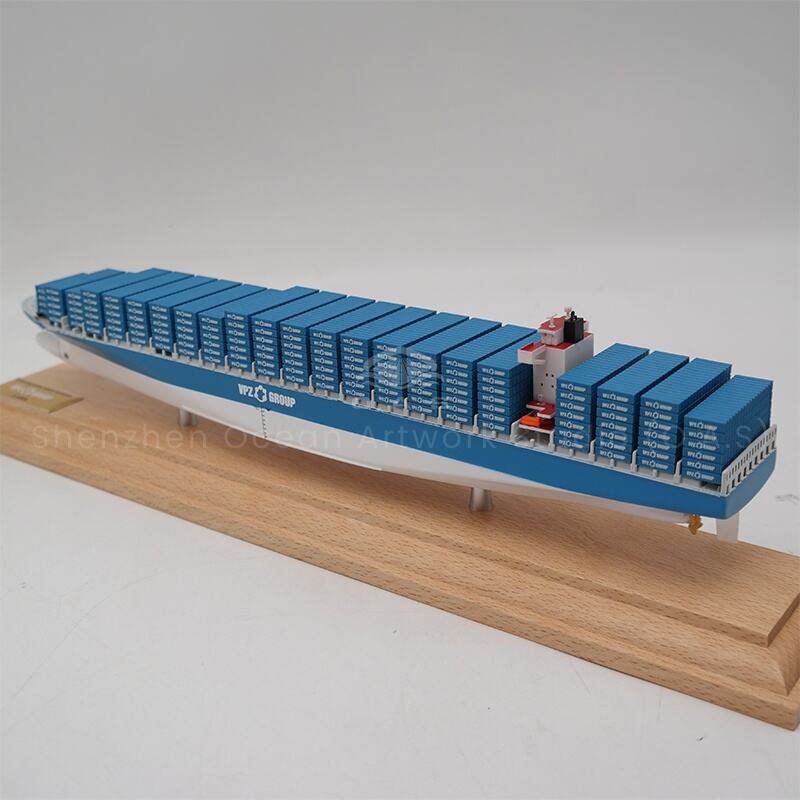

modèle de porte-conteneurs

Le modèle de porte-charbon est un navire maritime spécialisé conçu spécifiquement pour transporter de grandes quantités de matières sèches en vrac sur les routes maritimes mondiales. Ces navires constituent la colonne vertébrale du commerce international, facilitant le déplacement de matières premières essentielles qui alimentent les économies du monde entier. Le modèle de porte-charbon intègre des principes d'ingénierie avancés afin de maximiser la capacité de chargement tout en maintenant une efficacité opérationnelle et des normes de sécurité élevées. Les modèles modernes de porte-charbon sont dotés de systèmes sophistiqués de manutention des cargaisons, comprenant plusieurs cales séparées par des cloisons étanches qui empêchent le déplacement du chargement pendant le transport. La conception structurelle du navire met l'accent sur la durabilité et la résistance, avec une construction en acier renforcé capable de résister aux environnements marins difficiles et aux charges lourdes. Les caractéristiques technologiques principales incluent des systèmes de ballast perfectionnés assurant la stabilité du navire, des calculateurs informatisés de chargement qui optimisent la répartition des poids, ainsi que des équipements de navigation dernier cri garantissant une gestion précise des itinéraires. Le modèle de porte-charbon varie généralement de petits navires dits « handysize », capables de transporter entre 10 000 et 35 000 tonnes de port en lourd, à de gigantesques navires « capesize » pouvant transporter plus de 180 000 tonnes de marchandises. Ces navires peuvent acheminer diverses marchandises, notamment du minerai de fer, du charbon, des céréales, de la bauxite, du phosphate et d'autres matériaux en vrac indispensables à la production industrielle et aux chaînes d'approvisionnement alimentaire mondiales. Leur conception comprend des couvercles d'écoutilles étanches aux intempéries, protégeant la cargaison de l'eau de mer et des conditions climatiques défavorables, tandis que des systèmes de ventilation spécialisés préviennent la détérioration des marchandises pendant les voyages prolongés. Les modèles modernes de porte-charbon intègrent des technologies de protection environnementale, telles que des systèmes de traitement des eaux de ballast et des équipements de réduction des émissions, répondant ainsi aux exigences contemporaines en matière de durabilité. La flexibilité opérationnelle de ces navires permet des opérations portuaires efficaces grâce à des capacités d'autodéchargement ou à une compatibilité avec des équipements de manutention terrestres, faisant du modèle de porte-charbon un composant indispensable des réseaux logistiques maritimes mondiaux.