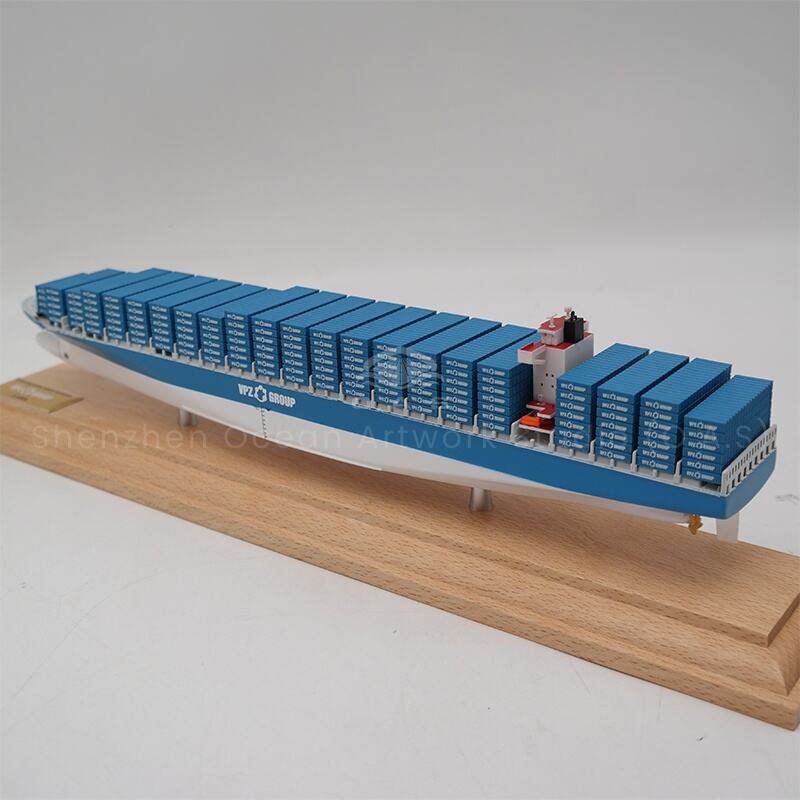

ship construction model

The ship construction model represents a revolutionary approach to maritime vessel development, integrating advanced engineering principles with cutting-edge digital technologies. This comprehensive system encompasses every phase of shipbuilding, from initial conceptualization through final delivery, providing stakeholders with unprecedented visibility and control over the construction process. The ship construction model serves as a digital twin that mirrors real-world shipbuilding operations, enabling precise planning, resource allocation, and quality management throughout the entire project lifecycle. At its core, this innovative framework combines 3D modeling capabilities with project management tools, creating a unified platform that streamlines communication between designers, engineers, contractors, and clients. The technological features of the ship construction model include parametric design capabilities, automated material calculations, real-time progress tracking, and integrated quality assurance protocols. These features work together to minimize construction errors, reduce material waste, and accelerate project timelines. The model incorporates advanced simulation technologies that allow teams to test various design scenarios before physical construction begins, significantly reducing the risk of costly modifications during the building phase. Applications of the ship construction model span across diverse maritime sectors, including commercial shipping, naval defense, offshore oil and gas, luxury yachting, and specialized research vessels. The system adapts to different vessel types and sizes, from small recreational boats to massive cargo carriers and complex offshore platforms. By leveraging cloud-based technologies, the ship construction model enables global collaboration, allowing international teams to work seamlessly on complex projects regardless of geographical boundaries. This digital approach transforms traditional shipbuilding practices, replacing paper-based processes with dynamic, interactive models that provide real-time insights into construction progress, resource utilization, and potential bottlenecks.