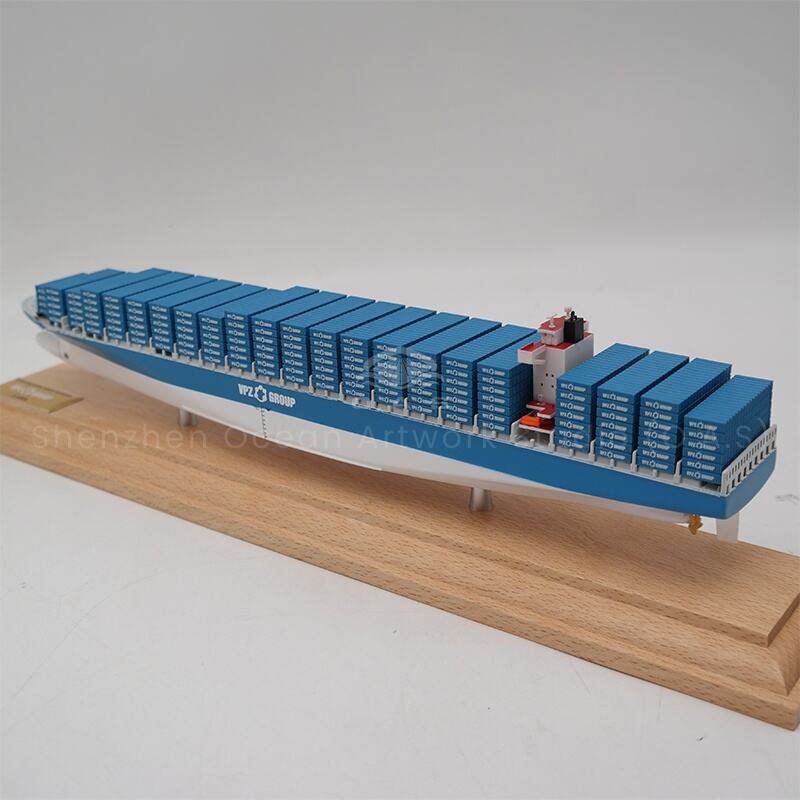

Intelligent Cargo Management System

The china shipping boat model features an state-of-the-art intelligent cargo management system that revolutionizes how shipping companies handle freight operations and maximize vessel utilization. This comprehensive system integrates advanced sensors, automated loading mechanisms, and real-time tracking capabilities to streamline cargo handling processes from port to port. Smart containerization technology automatically calculates optimal loading configurations based on cargo weight, dimensions, and destination requirements, ensuring maximum space utilization while maintaining proper weight distribution for vessel stability. The system includes automated crane operations that reduce loading and unloading times by up to forty percent compared to manual processes, significantly improving port turnaround efficiency. Real-time cargo monitoring provides continuous updates on shipment status, temperature control for sensitive goods, and security alerts that protect valuable freight throughout the voyage. The china shipping boat model incorporates flexible hold configurations that adapt to different cargo types without requiring extensive modifications, enabling operators to accept diverse shipping contracts and maximize revenue opportunities. Digital inventory management tracks every item loaded onto the vessel, creating detailed manifest records that facilitate customs clearance and delivery coordination. Climate control systems maintain optimal conditions for temperature-sensitive cargo, including pharmaceuticals, food products, and electronic equipment, ensuring product integrity throughout transportation. Advanced tie-down systems secure cargo automatically during rough weather conditions, preventing damage and maintaining vessel stability. The intelligent routing system coordinates cargo delivery schedules with optimal sailing paths, reducing delays and improving customer satisfaction. Integration with port management systems enables seamless information exchange that expedites cargo handling procedures and reduces administrative overhead. Predictive maintenance algorithms monitor cargo handling equipment performance and schedule maintenance activities to prevent operational disruptions. The system generates comprehensive reports that help operators analyze cargo handling efficiency and identify opportunities for further optimization, supporting continuous improvement in shipping operations.