The art of creating authentic truck models has evolved significantly in recent years, with collectors and enthusiasts demanding increasingly realistic representations of their favorite commercial vehicles. When you customize truck models, you're not just building a miniature replica—you're preserving the legacy and visual identity of iconic transportation brands. This comprehensive guide will walk you through the essential techniques, materials, and strategies needed to transform basic model kits into stunning branded masterpieces that capture every detail of real-world vehicles.

Before you begin any customization project, thorough research forms the foundation of success. Professional modelers understand that to customize truck models effectively, you must first study the original vehicle's specifications, color schemes, and distinctive markings. Start by collecting high-resolution photographs from multiple angles, including close-ups of logos, decals, and unique design elements. Many trucking companies have specific brand guidelines that dictate exact color codes, font styles, and logo placement requirements.

Documentation should extend beyond visual elements to include historical context and operational details. Understanding when certain liveries were introduced, which model years featured specific modifications, and how branding evolved over time will inform your customization decisions. This research phase often reveals subtle details that separate amateur attempts from professional-grade reproductions that truly capture the essence of the original vehicle.

Achieving accurate color reproduction requires sophisticated color matching techniques that go beyond basic eyeball comparisons. Professional model customizers maintain extensive libraries of paint samples and use specialized tools like colorimeters to ensure precise matches. When you customize truck models for specific brands, remember that commercial vehicle paints often differ significantly from standard automotive finishes in terms of durability, finish type, and color saturation.

Many manufacturers use unique color formulations that have evolved over decades, creating slight variations even within the same brand family. Document these variations carefully and consider the specific era you're modeling. A Peterbilt from the 1970s will have different paint characteristics than a contemporary model, even when using supposedly identical colors. This attention to historical accuracy separates exceptional custom work from generic reproductions.

Investing in quality painting equipment dramatically improves your ability to customize truck models with professional results. Airbrush systems provide the smooth, even coverage necessary for large surface areas like cab sides and trailer panels. Choose airbrushes with adjustable needle assemblies that allow for both broad coverage and fine detail work. Compressors should maintain consistent pressure and include moisture traps to prevent paint contamination.

Beyond basic airbrush equipment, consider specialized tools like paint mixers, color matching lights, and precision masking materials. High-quality masking tape and film ensure clean lines when applying multi-colored schemes or complex graphics. Many professional modelers use vinyl cutting machines to create perfectly shaped masks for intricate logo work, eliminating the guesswork involved in hand-cutting complex shapes.

Modern decal technology has revolutionized how modelers customize truck models, offering unprecedented accuracy and durability. Desktop printers capable of handling clear decal film allow for custom graphics that match original specifications perfectly. When creating decals, use vector graphics software to ensure crisp edges and proper scaling across different model sizes.

Application techniques require specific tools and environmental controls for optimal results. Decal setting solutions help conform graphics to curved surfaces and eliminate air bubbles, while specialized squeegees ensure proper adhesion without damaging delicate printed elements. Temperature and humidity control during application prevents premature drying and allows for repositioning when necessary.

Photo-etched parts represent the pinnacle of detail accuracy when you customize truck models for exhibition or competition purposes. These precisely manufactured components replace molded plastic details with ultra-thin metal parts that capture fine features impossible to achieve through traditional manufacturing methods. Grilles, step plates, exhaust systems, and cab accessories benefit tremendously from photo-etched upgrades.

Working with photo-etched parts requires specialized techniques and tools. Sharp hobby knives, fine-pointed tweezers, and appropriate adhesives are essential for successful installation. Many experienced modelers pre-paint photo-etched components before installation, using techniques like dry brushing to highlight raised details and create realistic weathering effects that enhance the overall authenticity of the finished model.

Incorporating functional lighting systems adds remarkable realism to custom truck models, bringing static displays to life with authentic illumination patterns. LED technology has made it practical to customize truck models with working headlights, marker lights, and even animated turn signals. Planning the electrical layout during early construction phases prevents complications later in the build process.

Fiber optic systems offer alternatives for models where LED installation proves challenging. These systems can distribute light from a single source to multiple locations throughout the model, creating realistic lighting effects without the complexity of individual LED installations. Battery compartments must be discreetly integrated to maintain the model's aesthetic appeal while providing reliable power for extended display periods.

Accurate logo placement requires careful measurement and scaling to maintain proper proportions relative to the model's size. When you customize truck models, remember that real vehicles follow strict branding guidelines that specify exact logo dimensions and positioning. Use calipers and precision rulers to transfer these measurements to your model scale.

Consider the viewing angles when positioning logos and graphics. Elements that appear prominently from certain perspectives may be barely visible from others. Professional customizers often create multiple versions of the same logo at different scales to ensure optimal visibility and impact from the model's primary display angle. This attention to visual hierarchy creates more compelling and realistic presentations.

Realistic weathering transforms pristine custom models into authentic representations of working vehicles. Study how real trucks age and wear, paying attention to high-contact areas, exposure patterns, and maintenance cycles. Different materials weather at different rates, creating complex patina patterns that tell the story of the vehicle's service history.

Weathering techniques should complement rather than overwhelm the branding elements. Subtle fading around decals, slight wear on raised surfaces, and carefully applied dirt and grime effects add realism without masking the customization work. Progressive weathering allows for adjustments throughout the process, building up effects gradually until the desired level of authenticity is achieved.

Systematic quality control ensures that efforts to customize truck models result in exhibition-worthy pieces. Develop standardized inspection procedures that examine every aspect of the customization, from paint uniformity to decal adhesion. Use magnification tools to identify imperfections that might not be visible during normal construction but become apparent under display lighting.

Touch-up procedures should address both cosmetic and structural issues before final assembly. Keep detailed records of paint formulations and application techniques used during the initial work to ensure consistent results during touch-up operations. Many professional modelers photograph their work at various stages to document successful techniques and identify areas for improvement in future projects.

Protective coatings preserve customization work and extend the model's display life significantly. Clear coat systems provide UV protection, prevent decal degradation, and allow for safe cleaning without damaging underlying work. Choose coatings appropriate for the specific materials and techniques used in your customization process.

Application techniques for protective coatings require the same precision as primary paint work. Thin, even coats prevent runs and maintain surface detail, while proper curing conditions ensure maximum durability. Consider the final display environment when selecting coating systems, as indoor and outdoor display requirements differ substantially in terms of UV resistance and moisture protection.

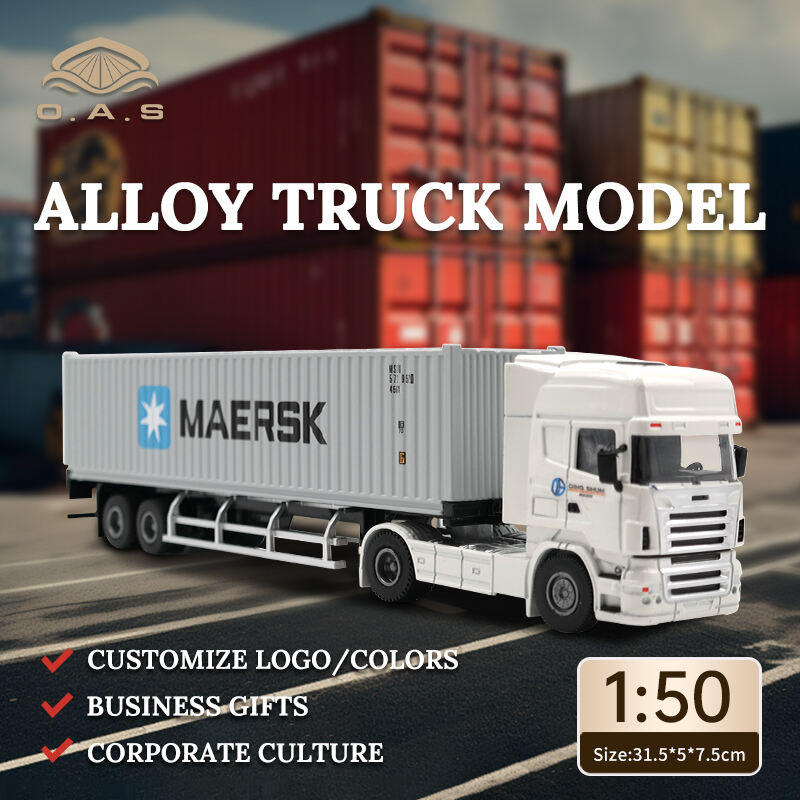

The 1:50 scale offers an excellent compromise between available detail and reasonable cost for most collectors who want to customize truck models. This scale provides sufficient surface area for detailed graphics while maintaining manageable size requirements for display and storage. Parts availability and aftermarket support are typically strong in this scale, making customization projects more feasible for hobbyists with moderate budgets.

A comprehensive customization project typically requires 40-80 hours of work spread over several weeks or months, depending on complexity and your experience level. When you customize truck models to professional standards, allowing adequate drying time between paint coats, proper curing for adhesives, and careful attention to detail significantly impacts the timeline. Rush projects often compromise quality, so plan accordingly for the best results.

While airbrush systems provide superior results, skilled modelers can customize truck models using high-quality brush techniques and rattle can paints. Success depends on proper surface preparation, thin paint coats, and patience during application. However, for complex multi-color schemes and large surface areas, airbrush equipment becomes almost essential for achieving professional-looking results that match original vehicle specifications.

Manufacturer service manuals, parts catalogs, and official brand style guides provide the most reliable color information when you customize truck models. Online forums dedicated to specific brands often share detailed color matching information gathered by experienced enthusiasts. Paint manufacturers like Tamiya and Mr. Color frequently offer color conversion charts that translate real-world paint codes into model-appropriate formulations for accurate reproduction.

Hot News

Hot News2024-06-11

2024-06-07

2024-06-01

2024-06-01

2024-06-01

2024-05-25